Vale-Tech, UK

Established in 1985, Vale-Tech Ltd specialises in the design and manufacture of dispensing equipment for the paint and printing industries.

Based just outside Cambridge in the UK, Vale-Tech Ltd employs a team of software and hardware design engineers dedicated to the design and build of innovative products that incorporate the latest technology.

Today Vale-Tech Ltd is a major global supplier of dispensing systems, with more than 1,200 systems installed in over 50 countries within Europe, Asia, Russia, Middle East, Australasia and the USA.

Vale-Tech Ltd’s product portfolio provides a comprehensive range of dispense systems to meet the needs of both small and large companies.

Vale-Tech Ltd’s dispensing range includes systems suitable for dispensing conventional and UV curing, Flexo and offset inks.

For additional information, including brochures for Vale-Tech’s dispensing and decanting systems, please go to our download section, contact Novasys or visit the Vale-Tech Ltd website at www.vale-tech.co.uk

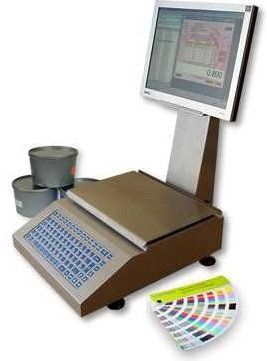

Vale-Tech Colour Pack Checkweigh System

Colour Pack comprises a compact PC connected to a high accuracy balance, and is used for ink management and manual blending in Offset, Flexo, Screen & Gravure in-plant operations where a fully automatic dispenser is either unjustified or unsuitable.

Vale-Tech’s Ink Manager™ is a powerful software package meeting all the data storage and retrieval requirements of a modern in-plant dispense system with extensive reporting and costing utilities.

Used worldwide, this system provides a comprehensive formulae database coupled with estimation, re-work and job records.

It’s intuitive, graphical interface combines ease of use with extensive custom inbuilt reporting functions further enhanced by Microsoft Office connectivity to Word, Excel and Outlook.

This system combines accurate weighing with a comprehensive Formula database and full Stock Control features, ensuring colours are mixed quickly, accurately and consistently every time; saving time, ink and improving quality!

Vale-Tech CD20 Cartridge Ink Dispenser

The compact design of the Vale-Tech CD20 ink dispenser, coupled with high accuracy, makes it ideal for use in colour laboratories, ink kitchens and busy print shops. Suitable for Sheet-fed offset, Packaging and Textile printers or any application where paste inks or other high viscosity materials are used.

The CD20 is a fully integrated system designed to dispense from industry-standard disposable or refillable steel ink cartridges. Its unique design allows it to dispense into containers ranging from proofing cups to 5Kg pots.

The Vale-Tech Ink Manager™ software ensures complete control of the dispensing and colour blending process.

The CD20 is designed to dispense batches as small as 50g to an accuracy of 0.1g.

- Engineered for long life.

- Clean no-fuss operation.

- Instant on-demand colour mixing.

- Vale-Tech Ink Manager™ easy-to-use software.

- Software includes comprehensive database, and stock control.

- Compact design occupies a minimum of floor space.

- High reliability and low maintenance design.

- Remote access feature allows direct link to a colour centre or Technical Support Team for training and software maintenance.

- Installation is virtually plug and play.

- Fed from STANDARD Sonoco or Ritter Cartridges.

- Pantone Licensed Software.

- Unique anti-drip valve design.

- Manual add facility for special ingredients.

Vale-Tech Integra Ink Mixing Scale and PC

INTEGRA 2 is a complete Ink Management and Colour Control work station linked to the Vale-Tech Ink Manager™ Windows based software.

This compact, integrated computerised balance incorporates all of the benefits of a high specification PC and a high accuracy scale in one package. Its small footprint occupies the minimum of bench space.

Built to operate in hostile conditions, the weigh pan is manufactured in a high quality stainless steel with the case protected by a hard wearing, polyester powder coat incorporating a solvent safe, polyester based membrane keyboard.

Vale-Tech’s Ink Manager™ is a powerful software package meeting all the data storage and retrieval requirements of a modern in-plant dispense system with extensive reporting and costing utilities.

This system combines accurate weighing with a comprehensive Formula database and full Stock Control features. Integra 2 ensures colours are mixed quickly, accurately and consistently every time; saving time, ink and improving quality!

Vale-Tech HP10, HP25 and HP35 Paste Ink Dispensers

The Vale-Tech HP10, HP25 and HP35 are high-duty ink dispensers designed for 24/7 operation, and are very suitable for UV and conventional offset inks, concentrates, plastisols and high viscosity products.

Their compact design, high accuracy and ease of use make them the ideal systems for inplant colour blending. The HP10 is designed to dispense difficult high viscosity inks in batch sizes of 100g to 7Kg, while the HP25 dispenses batches up to 25kg.

HP series machines feature:

- PANTONE® licensed software.

- Long life dispense valves, fitted with Teflon seals and anti-drip nozzles.

- Incorporates the Vale-Tech range of high accuracy, stainless steel enclosed balances.

- Fixed ink reservoirs of 10kg or 20kg or 35kg capacity, depending upon model.

- Blending colour batches from 100g to 25Kg to an accuracy of +/- 0.1g

- Up to 24 ink reservoirs.

- Each ink reservoir incorporates an ink level sensor – Low ink warnings are given “real time”.

- Agitation option.

Benefits

- Compact, high accuracy, high performance ink dispensers with a small footprint requiring the minimum of space.

- High reliability and low maintenance.

- Installation is virtually plug and play.

- Remote access feature allows direct link with the ink supplier, colour centre and the Technical Support Team providing on-line training and software maintenance.

Vale-Tech IDS10 and IDS35 Inplant Ink Dispenser

The Vale-Tech IDS10 and IDS35 are particularly suitable for accurate dispensing of UV screen and UV flexo inks and varnishes.

The IDS10 and IDS35 Inplant Ink Dispensers are a smart, modular design developed with a singular purpose: to meet the highly demanding aesthetic requirements of a printing operation while accommodating the very practical functions of running an efficient business.

The many IDS installations have shown that these machines enable printed results of exceptional accuracy to be obtained – far superior to any other automated dispensing system in the industry. At the heart of the IDS10 and IDS35 dispensers, you’ll find precision manufactured dispensing valves with long life Teflon seals; accurate to +/-0.2g. With Vale-Tech Ink Manager software, you are ensured that everything you need to control colour and ink usage throughout the dispensing and colour blending process is available to you.

For printers who demand speed, accuracy and full audit trails for the dispensed product, the IDS10 and IDS35 are excellent solutions. Dispensing, mixing, and proofing functions of these machines are fully automated.

The IDS10 and IDS35 dispensers offer you considerable savings possibilities – The most obvious is the 20-45 percent cost savings in ink because you use only what you need. The speed of dispense enables you to provide ink to the press “just-in-time”, and in the actual quantity that they require. This means that there is no waste and no need to store unused product. Being fully automated, the IDS10 and IDS35 save you a large amount of production time, require less oversight, and allows you to increase your capacity to provide printing other services.

Features

- PANTONE® licensed software.

- Long life dispense valves, incorporating Teflon seals and anti-drip nozzles.

- Incorporates the Vale-Tech range of high accuracy, stainless steel enclosed balances.

- Fixed ink reservoirs of 10kg (IDS10) or 35kg (IDS35) capacity.

- Up to 24 ink reservoirs.

- Each ink reservoir incorporates an ink level sensor.

- Agitation option

Benefits

- Compact, high accuracy, high performance ink dispensers.

- A small footprint means these dispensers require minimum space.

- High reliability and low maintenance.

- Installation is virtually plug and play.

- A remote access feature.

Vale-Tech LV Large Volume Dispensing System

Vale-Tech’s LV system is suitable for dispensing UV and water-based, flexo, UV screen inks and varnishes.

The LV dispenser will accommodate up to 24 stand-alone pumps, each delivering inks or varnishes from bulk containers such as drums and totes. The system is configured to suit individual requirements and applications.

Any combination of pumps can be accommodated whether pumping from 205 litre/55 gallon drums, Totes or IBCs.

Benefits

- Eliminates the need to buy ready-mixed inks.

- Instant colour mixing on demand.

- High speed automatic colour dispensing.

- Accurate repeatability of blends.

- Re-work press returns.

- Compact design occupies minimum floor space.

- High reliability and low maintenance.

- Remote access feature allows direct link with the ink supplier, colour centre and the Technical Support Team providing on-line training and software maintenance.

- Comprehensive reporting capability.

Vale-Tech POD Paste Ink Dispenser for Small Batches

The Vale-Tech POD is a fully automatic compact dispenser designed to dispense into containers ranging from 10g to 2.5kg to an accuracy of +/-0.1 gram.

A pneumatically-operated cylinder mounted above the main dispense point presses the ink out of the container to the dispense head.

The “vacpack” supply containers (either 2.5 or 1 litre, steel or plastic) are supplied full by the ink manufacturer, relieving the user of the POD of any need to manual handle the ink.

The press-out system virtually empties the container.

- Compact construction means easy installation and re-positioning, if necessary.

- Will dispense into containers of 100mm diameter or larger.

- Dispense accuracy of 0.1g.

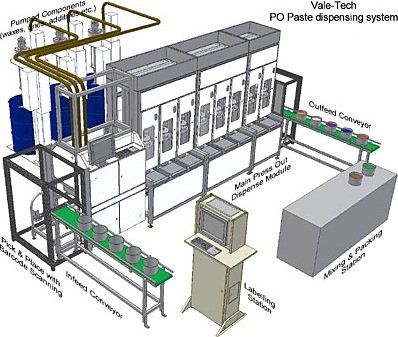

Vale-Tech PO20 Paste Ink Small Batch Dispenser

The PO20 dispenser is a medium duty, integrated press-out system, designed for high viscosity printing ink ranges such as offset and concentrates.

Bringing high reliability, compact size and simple operation together, Vale-Tech has designed the ideal vehicle for higher productivity, reduced ink wastage and significantly improved colour control.

The PO20 is constructed as a standalone, fully integrated machine incorporating up to 24 ink reservoirs, each with a capacity of 20Kg.

It is compact in design with a footprint of 140mm x 2,500mm for a typical 12 colour system.

Options are available for external pumped modules to allow the dispensing of all bulk components such as high

pigmented base inks, varnishes and extenders from 205 litre barrels or IBCs.

Vale-Tech Single Ingredient Dispensers and Filling Systems

Vale-Tech manufacture a wide range of filling systems and single-ingredient bulk dispensers.

The filling systems are used to “pot off” bulk production of ink or paint into smaller containers which are then supplied to the manufacturer’s customers.

Vale-Tech filling systems significantly increase throughput when compared to manually operated filling operations, through saving time, improving accuracy, eliminating human error and reducing giveaway.

Automatic record keeping provide traceability.

Single ingredient dispensers are widely used to decant bulk materials (white, clear bases or varnishes, etc) from 200 litre barrels or 1,000 litre IBC/totes into more easily handled 1, 5 or 20 litre containers in the Printing and Paint industries.

Vale-Tech P2P – Pump to Press

The Vale-Tech P2P is a fully integrated system occupying a minimum of floor space, designed to ensure that CMYK inks are distributed quickly and cleanly directly to the press fountains from bulk containers.

Vale-Tech air-driven piston pumps deliver the inks from 200kg drums via a hard piped distribution network to ink spreader bars mounted on each print unit.

The P2P system comprises an Operator Controller unit (OC) networked to a Feed Controller mounted on each print unit. Connected to the Feed Controller is an ink feed valve and fountain-mounted ink spreader bar that incorporates a precision ultrasonic sensor that controls the pumping system, ensuring that ink level is maintained within operator-set high and low limits. An alarm is activated if these levels are breached.

Vale-Tech PM110 Offset Ink Mixer

The perfect small batch mixer for offset inks.

The PM110 is capable of mixing blends from 500g right up to 10kg in industry-standard ink containers.

A simple disc mixing blade is driven by a powerful variable speed drive ensuring high viscosity inks are quickly and thoroughly blended.

Designed to mix all types of UV and conventional paste finished inks and concentrates, all moving parts of the PM110 Offset Ink Mixer are safely enclosed in a closed cabinet. A programmable speed controller ensures the optimum speed and mix cycle can be preset.