Tecnopails Launches the Matrix series filling system with Rexson Paint Dispensing

Tecnopails, the dedicated filling division of IM GROUP (formerly Inkmaker Group), has launched a new feed and closure filling-line series—with a specific line dedicated for integration with Rexson’s ColorPoint paint dispenser.

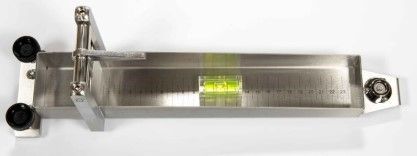

The robust system, capable of expanding from manual through to fully automatic solutions, was named the “Matrix” due to its ability to be easily configured through a variety of adjustable modules. One such module is the Matrix+Rexson/Colorpoint created especially for integration with IM GROUP’s “Easypaint” solution. The Easypaint concept is IM GROUP’s most flexible and complete range of automatic dispensing solutions, tailored to meet precise performance and productivity targets while maximising available space and minimising manpower.

“This is yet another example of IM GROUP’s brands working in unison to achieve innovation for the group. The Matrix has been in the research and planning stage since early last year, and we were very proud to launch it at Eurocoat Paris this year. The series features some of the latest IIoT touchscreen and industry-4.0-smart technology from Inkmaker’s renowned software and automation team. We’d particularly like to congratulate all our colleagues involved on this momentous achievement,” commented Gianluca Incerti, Global Director of Sales, IM GROUP.

The Matrix comes just three months after Tecnopails launched the "Lavelli A21", for coupling lids with latches, which at the time made international news for being a world first for liquid paints.

“What makes the Matrix, feed and closure filling-line system, so innovative is that it is totally configurable through six variations of adjustable modules that enable the filling line system to be expanded from the manual M1 and M2 to the semi-automatic SA1 and SA2 or to fully automatic A1 and A2 solutions. This is undoubtably an attractive proposition for any client, be they large or small,” concluded Olivier Daulon, General Manager, Inkmaker France.

A special launch film was created by IM GROUP’s internal communication agency, THINK, to highlight the Matrix’s unique features and is for public viewing on the group’s YouTube channel at

https://www.youtube.com/channel/UCNfFEtbc9peXZdmewXW3miQ

Tecnopails, which was acquired by IM GROUP early last year and specialises in the design and production of customised automated systems for dosing, sealing and labelling for Ink, paint and chemical containers.

#inkmaker #tecnopails #rexson #paintfilling #paintdispensing #matrixfilling