Rhopoint Instruments, UK

Rhopoint Instruments Ltd. has been producing test equipment since 1975. They are leading manufacturers in the supply of optical and laboratory instruments for the Surface Coatings industry.

With their own design, manufacture and marketing facilities in the UK, their mission is to build instruments to the highest standards of accuracy and reliability that exceed their customers’ expectations.

Rhopoint’s Novo-Gloss single and multi-angle glossmeters, Novo-Curve curved surface glossmeters and Rhopoint IQ Goniophotometer, along with their PAINTLAB+ range of flow cups and viscometers, are widely used in quality assurance applications in many different industries throughout Australia and New Zealand.

Novasys can provide calibration and repair services for all Rhopoint instruments, as required.

For additional information, including brochures for Rhopoint’s instruments, please go to our download section, contact Novasys or visit Rhopoint Instruments’ website at www.rhopointinstruments.com

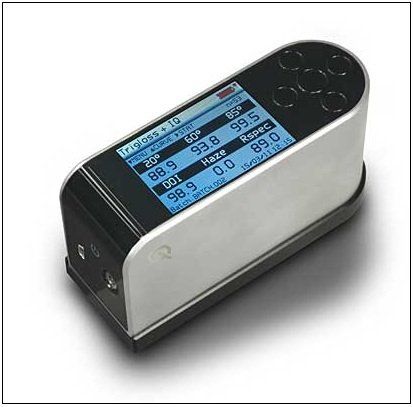

Rhopoint IQ Goniophotometer, DOI Meter, Hazemeter and 20′/60′ or 20′/60′/85′ Glossmeter

The Rhopoint IQ quantifies surface quality problems that are invisible to a standard glossmeter!

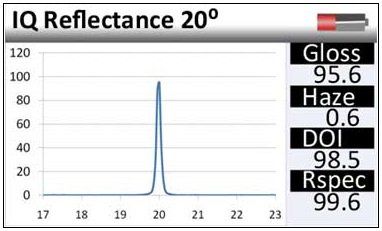

The Rhopoint IQ measures image quality – It is the only hand-held instrument that profiles how light is reflected from a surface. Standard glossmeters only measure how much light is reflected and are not sensitive to effects which dramatically reduce appearance quality.

Whilst glossmeters are widely used throughout industry to assess the reflective qualities of products, gloss information alone is limited as it tells us how much light is reflected, but nothing about the imaging forming qualities of a surface.

Phenomena such orange peel, haze effects and polishing marks distort reflections in a surface, seriously reducing visual appearance but cannot be measured with a traditional glossmeter. This means two surfaces which have very different reflective properties often have exactly the same gloss value.

The New Rhopoint IQ can measure all aspects of Reflective appearance quality. The Rhopoint IQ measures GLOSS, HAZE and Distinctness of Image – Complete reflective appearance analysis in a single reading, allowing you to quantify and control the surface textures that reduce the perceived quality of manufactured products.

Paints and coatings manufacturers and applicators, wood coatings, automotive industry, plastics and additives manufacturers, inks and printing, metal polishers, coil coaters, yacht manufacturers and powder coaters are amongst the many industries that are currently assessing surface quality using Rhopoint IQ technology.

The unique all aluminium construction of the Rhopoint IQ provides strength and rigidity in the instrument providing you with improved accuracy and reliability over previous generations of gloss instruments.

A full colour, high definition screen and five way touch sensitive buttons make the instrument incredibly easy for you to read and operate.

The features of the Rhopoint IQ can be switched on and off independently – the instrument can be configured as a fully functional 20/60/85° Gloss-Haze-DOI-Goniophotometer with memory or as a simple single, dual or triple angle non-statistical glossmeter.

Each Rhopoint IQ instrument is supplied with an ISO 17025 laboratory calibrated standard with detailed traceability to BAM and stated uncertainty. This high level of traceability is required for automotive, defence, pharmaceutical and other similar applications.

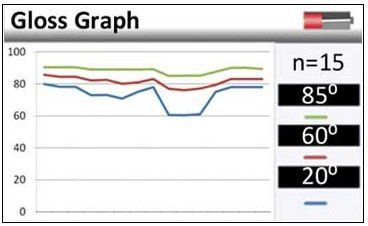

The Rhopoint IQ displays statistics for all measured parameters – It also displays full colour trend graphs on the instrument screen giving you a detailed understanding of the sample quality without the need to download results to a spreadsheet.

Results from the Rhopoint IQ can be imported directly to a PC/MAC without downloading or installing any special software – Plug the instrument into any computer and the onboard memory is accessed like a USB drive. Results are stored as industry-standard CSV files that can be displayed in spreadsheet programs such as Excel.

Rhopoint Instruments Ltd are so sure of the reliability of the Rhopoint IQ that the instrument is supplied to you with a FREE 2 years manufacturer’s warranty, AND…… If you buy a Rhopoint IQ, Rhopoint guarantee that you will be delighted with the quality and performance of the instrument – If not, you can return it within 30 days of delivery for a full refund of the instrument price.

Rhopoint Novo-Gloss Single, Dual and Triple Angle Glossmeters for Flat Surfaces

Reliable, accurate and priced to suit every budget, Rhopoint Novo-Gloss instruments are available in single, dual and triple angle formats for all gloss measurement applications.

The Novo-Gloss 20/60/85 gloss meter is a fully featured, extremely easy to use instrument measuring the gloss of all flat surfaces.

The 60º is the reference angle and is be used to measure any surface from matt to mirror finish.

To complement this the instrument also has 20º for improved measurement on high-gloss surfaces and 85º which gives improved resolution on matt surfaces.

The 60º angle on the Novo-Gloss 20/60º is the reference angle for gloss measurement and can measure any surface from matt to mirror finish. The 20º geometry is designed for improved measurement resolution on high gloss finishes.

All Novo-Gloss instruments incorporate an easy-to-read, full colour screen and Bluetooth data transfer to instantly transmit measured readings directly into programs such as Microsoft Excel on your PC. (The instrument stores in excess of 1,000 measurements.)

A rechargeable lithium ion battery provides 17+ hours of operation and the capability to measure more than 10,000 readings per charge.

Integrated statistic analysis make the Rhopoint Novo-Gloss the perfect instrument for QC or batch analysis of samples.

Rhopoint IQ Flex 20

Unlike a standard glossmeter the Rhopoint IQ Flex 20 has the unique capability of measuring and detecting quality problems caused by microscopic texture in the surface that cause haze and orange peel effects which lead to poor Distinctness Of Image (DOI),

These factors can seriously affect the visual impact and reflective quality of many coated, painted and polished surfaces. By measuring the quality of the reflected image it accurately profiles how light is reflected from a surface.

Advanced measurement technology allows this instrument, in a single, fast measurement, to calculate Gloss, Haze, DOI, RIQ and RSpec providing the user with a complete analysis of the reflective quality of the surface.

The Rhopoint IQ Flex 20 is specifically designed for measuring curved surfaces, delicate parts and in-line measurement. Reduced measurement sizes, bespoke adapter jigs, including non-contact plates, and rubber, felt or plastic adapters expand this instrument’s areas of use in your plant.

Rhopoint Novo-Curve Glossmeters for Convex and Concave Surfaces

The Rhopoint Novo-Curve is a unique instrument with specially designed optics for accurately measuring curved surfaces and small areas. It can also be used to measure flat surfaces and areas which are too small to measure with standard glossmeters. With built in statistical analysis and the ability to download results to a PC the instrument has all the features you will ever need for fast accurate curved surface gloss measurement.

The Novo-Curve features:

• Measurement of curved AND flat surfaces

• Measures using the 60º geometry

• The measuring of small, curved or irregular surfaces is easy

• Simple jigging system is available, if required

• Bench top instrument

• Hands free operation is possible, making sample manipulation much easier

• Full statistical analysis

• Constant read feature

• Measures matt to mirror finishes

• Download, analyse and store readings in Novo-Soft PC software

• Extended two year warranty available FREE!

Rhopoint Novo-Shade Duo+ Reflectometer

The Novo-Shade Duo+ is a portable 45/0° reflectometer that can be used to assess either the shade of a surface (a simple indication of colour based on lightness/darkness) or calculate the opacity of a coating, plastic film or paper sample.

Measuring using 0/45º, the Novo-Shade Duo+ measures the colour of a surface and not the specular reflectance (gloss). In Shade Mode the Novo-Shade Duo can help maintain the production quality of the following:

• Shade of paints, inks and coatings

• Fading of textiles and plastics

• Chalking of paint

• Efficiency of detergents and bleaching agents

• Whiteness of recycled paper

• Cleanliness and oxidisation on metal surfaces

Substantial savings can be achieved by accurately measuring the hiding power of a coating formulation. It is often possible to reduce the amount of expensive opacity modifying agents in the coating whilst maintaining the required hiding power. Even marginal reductions in raw materials such as Titanium Dioxide can add up to significant savings over several batches of product.

Measuring the opacity of printed flexible packaging can also lead to cost savings for the printer. The applied film weight of an opaque coating can often be reduced by 20% whilst maintaining the hiding power required in the finished film.

The Rhopoint Novo-Shade Duo+ is a dual function reflectometer that can accurately measure these values.

The instrument has all the features found in the Novo-Gloss range:

- Full colour, easy to read display

- On-board statistics and graphs (in shade mode only)

- Touch sensitive keypad

- USB results download to your PC.

- Bluetooth connectivity

- Battery recharge by either USB or mains supply

- Automatic calibration with tile verification

- Pass/fail parameters are user definable (in shade mode only)

- Full traceability to National Standards.

- Automatic calculation of opacity and cleanliness

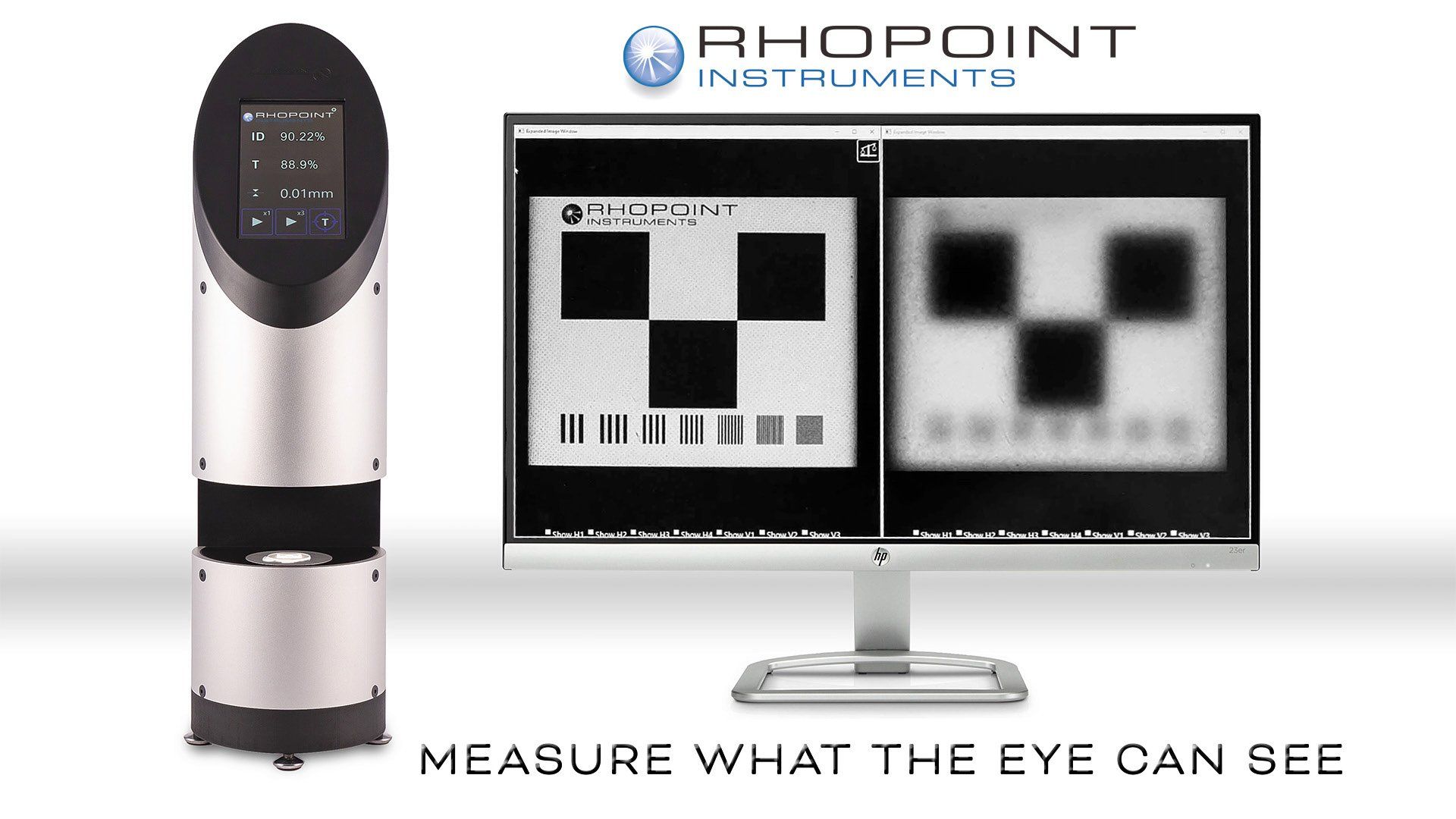

Rhopoint ID

The Rhopoint ID was developed in response to an industry call to find an improved method for characterising the transmission characteristics of transparent materials.

Packaging materials are typically required to be highly transparent in order to reproduce the vivid colours and finer details of the product, while cosmetics may require high opacity.

The Rhopoint ID quantifies the loss of transparency as Illumination Diffusion (ID), precisely capturing the visual effects of diffuse scattering of illumination light as it passes through a material.

Based on an imaging method, it is configured to match your perception of transparency.

The instrument outputs in-contact optical properties, as well as their variation with specimen-to-object separation distance, while on-demand probing local or spatially-averaged specimen areas.

Conventional measurement methods using a dedicated “haze-meter” exhibit a number of weaknesses, including not correlating directly with what we see, not capturing the variation in a material’s transparency with the separation distance between the material and the viewed object (Important for packaging materials which specifically target contact or non-contact applications,) and only giving a single value averaged over a large, (about 5 square cm,) area, which limit their effectiveness as an optical quality control tool for detecting local defects.

For more information on why you should consider the Rhopoint ID, please contact Novasys.

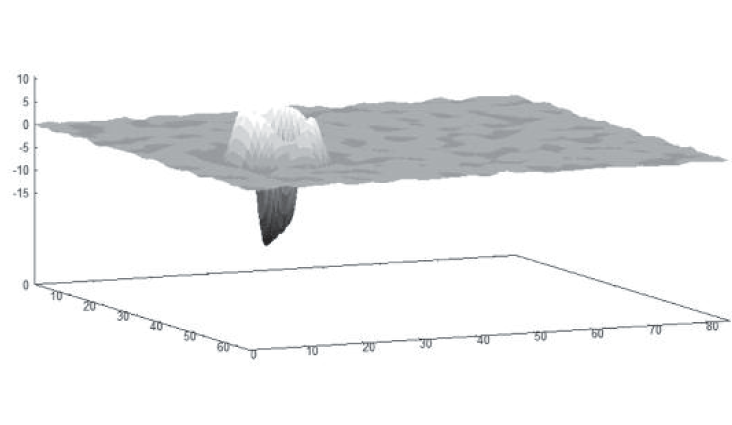

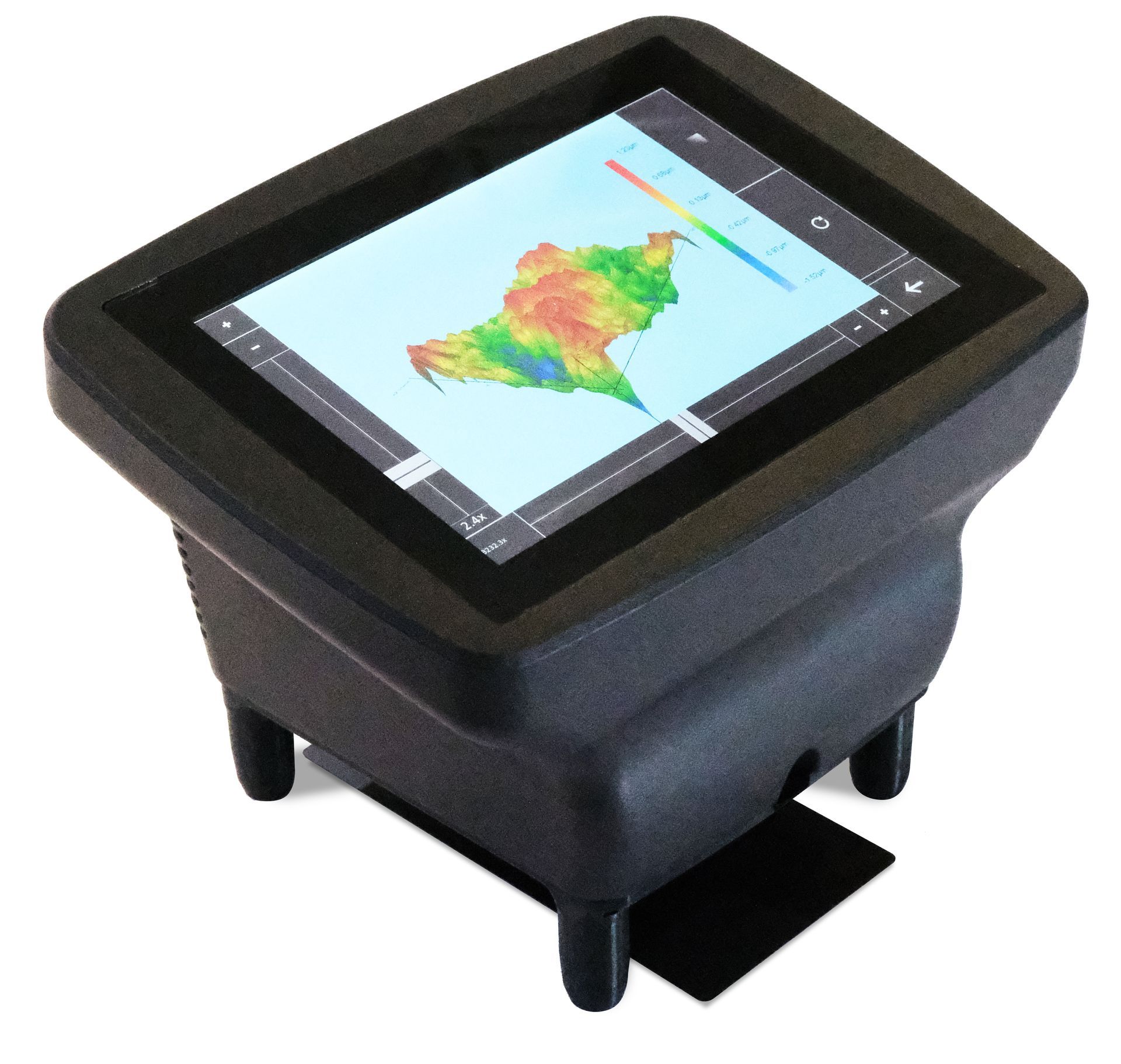

Optimap 3 PSD

ADVANCED SURFACE METROLOGY

- Fast full field surface measurement

- Suitable for all finishes, from matt to mirror

- On-screen image analysis

- Powerful analysis with portability

Optimap3 , the unique portable solution for surface inspection, allows rapid large area measurement and analysis of all types of coated or uncoated surfaces. Powerful on-screen functionality includes cross-sectional viewing allowing detection and characterisation of common surface irregularities including defects and waviness.

In quality control, inferior surface evaluation methods are still commonplace. Many methods lack definition, are time consuming and subjective. Modern consumers demand high quality products with surface finishes that are homogenous and free from defects. The use of Optimap3 provides a unique solution to these measurement challenges providing quantifiable data for improved production control.

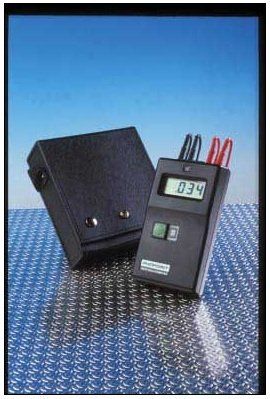

Rhopoint M210 Milliohmmeter

This battery operated, portable digital resistance meter is designed to measure accurately low resistance from 0.001 ohm to 200 ohms, using four-terminal measurement network which eliminates errors caused by test lead resistance.

The Rhopoint M210 Milliohmmeter instrument is small and light weight and is used easily in one hand with only an ON button to operate. It has auto-ranging, auto-decimal point and auto-powerdown after three minutes. It has long battery life and is powered by a single PP3 or MN 1604 battery.

Some typical applications include the checking of relays, switch and connector contacts, PC-plated through holes, PC track resistance, Transformer and motor windings, Ring circuit testing, Earth conductor continuity, Wire-wrapped and solder joints and RFI shielding and coil resistance.

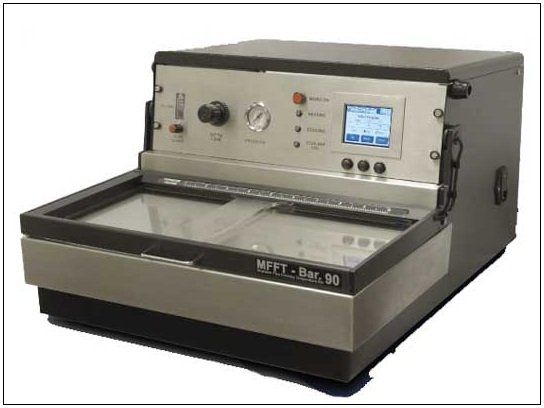

Rhopoint MFFT Minimum Film Forming Temperature Instruments

Minimum Film Forming Temperature (MFFT) is the lowest temperature at which a latex, emulsion or adhesive will uniformly coalesce when laid on a substrate as a thin film. An accurate MFFT value allows the formulation of products that cure correctly under specified application conditions.

Used in major coatings laboratories worldwide, the Rhopoint MFFTB is the industry standard instrument for characterising the curing performance of water based films in different application conditions.

The Rhopoint MFFT is the industry leading instrument for measuring the minimum film forming temperature of water based materials.

The Rhopoint MFFT works by holding a very accurate temperature gradient across a nickel plated copper platen. A flow of dried air across the platen stops condensation forming and gives repeatable test conditions. The Rhopoint MFFT conforms to ISO 2115 and ASTM 2354 methods.

Novo-Haze TX Transmission Haze

- Measure total transmission and haze

- Complies to ASTM D1003 (CIE C)

- Suitable for plastic film and other transparent materials

The Novo-Haze TX Transmission Hazemeter offers fast and accurate measurement of the optical quality of plastic films and other transparent materials.

This instrument measures total transmission and haze according to ASTM D1003 (CIE C), the most important standard used in most QA applications.

Manufactured in direct response to industry requirements, the Novo-Haze TX is offered at huge savings compared to other instruments which contain additional superfluous test methods.

The instrument features an intuitive user friendly interface which minimises the test time and makes it an ideal choice for both QC and R&D.

Uncompromising design, high quality materials and European manufacture make the Novo-Haze TX the ideal choice for any laboratory or QA environment.

At 50% of the price of the market leader for only measuring to this standard (ASTM D1003, CIE C), the Rhopoint Novo-Haze TX represents huge savings without compromising measurement accuracy.

Novo-Gloss Flex 60 Gloss-meter

- Measure small surface areas

- Measure curved and hard to reach surfaces

- On board statistics, Bluetooth and USB data transfer

- Enhanced accuracy measurement of low gloss finishes

Designed specifically to measure the gloss of surfaces that cannot be measured using traditional gloss-meters, the Novo-Gloss Flex 60 gloss-meter combines the functionality and reporting of an advanced gloss-meter with an ultra lightweight remote measuring head. IMPROVED PERFORMANCE IN LOW GLOSS APPLICATIONS The Novo-Gloss Flex 60 has been designed specifically to measure low gloss surfaces. It features an additional measuring scale with a resolution 10 times greater than standard glossmeters. This increased resolution gives a far superior level of control of surface finish. The Novo-Gloss Flex 60 complies to ISO 2813 and ASTM D523 and measurements made with the instrument are compatible with traditional gloss-meters complying to these standards.