Hanatek Instruments, UK

The Hanatek range of products from Rhopoint Instruments is designed to fulfill the testing needs of the packaging and paper industry – From raw material through to finished products.

All high quality Hanatek instruments are manufactured in an ISO9001 environment.

Hanatek instruments enable you to add value by providing you with an understanding of the physical characteristics of your materials throughout their life cycle.

The Hanatek product range of test measurement equipment includes Crease and Board Stiffness Testers, Carton Board Creaser, Friction Testers, Film Thickness Gauge, Film Shrink Instrument and the Rub Proof Testers.

Hanatek sample preparation equipment enables products or raw materials to be prepared for testing in the most efficient manner possible, saving your time in production or the test laboratory.

All Hanatek products are backed up with years of experience in the packaging industry, and are covered by a comprehensive extended warranty.

Novasys provides comprehensive calibration and repair services for Hanatek instruments, as required.

For additional information, including brochures for Hanatek’s instruments, go to our download section, contact Novasys or visit Hanatek Instrument’s website at www.hanatekinstruments.com

Hanatek Compact Friction Tester

Hanatek Crease & Board Stiffness Tester CBT1

Hanatek – Carton Force Analyser

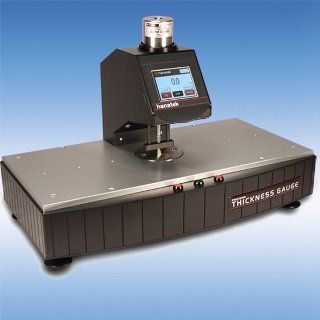

Hanatek FT3 Film Thickness Gauge

Hanatek Rub & Abrasion Tester RT4

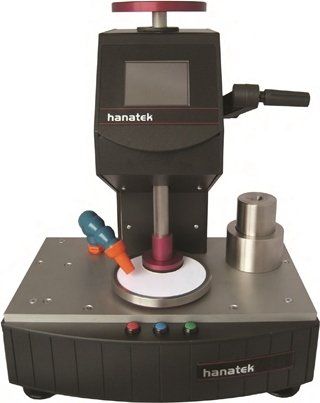

Hanatek – Universal Sample Cutter

The Hanatek Universal Sample Cutter has been designed for the simple cutting of samples for the packaging industry. Dies can be configured to cut samples for most test types including: friction, tensile, grammage, O2 permeability, CO2 permeability, WVTR, rub resistance, carton crease, carton stiffness and many more.